| $0=10 |

| $1=25 |

| $2=0 |

| $3=5 |

| $4=0 |

| $5=0 |

| $6=0 |

| $10=1 |

| $11=0.010 |

| $12=0.002 |

| $13=0 |

| $20=0 |

| $21=0 |

| $22=0 |

| $23=0 |

| $24=25.000 |

| $25=500.000 |

| $26=250 |

| $27=1.000 |

| $30=1000 |

| $31=0 |

| $32=0 |

| $100=1600.000 |

| $101=1600.000 |

| $102=1600.000 |

| $110=1000.000 |

| $111=1000.000 |

| $112=800.000 |

| $120=30.000 |

| $121=30.000 |

| $122=30.000 |

| $130=200.000 |

| $131=200.000 |

| $132=200.000 |

When using a laser in conjunction with a GRBL based CNC router such as the 3018 Pro, there is an important setting in GRBL which lets the CNC know what mode you want to be in. This setting is $32 and it can be edited in your command console by typing $32=1 to turn on Laser Mode, and can be turned off by typing $32=0. Optimize GRBL set up for 3810 GRBL mini CNC. View and Download SainSmart Genmitsu CNC 3018 user manual online. $6 = 0 (Invert probe pin, boolean) My $23=3 and here are my software settings. To download a copy of this cheat sheet, click the link below. When your engraving is too light then simply reduce your $30 setting.

- The CNC 3018-Pro router arrived with GRBL 1.1f installed on the Camtool V3.3 board and ran well enough, although it accelerated very slowly. After installing Home switches, figuring out the travel limits, and trying different speeds & accelerations, it runs much better.

- Hey Folks, First off im new to GRBL, lets make this known. So I've purchased a CNC model 3018 kit from ebay. It included a pre programmed Woodpecker 3.2 board. Now originally this board worked well but unfortunately I believe i managed to short the board out and damage it. I'm un able to communicate with the board. I've tried a lot of different things. Luckily I just so happened to have a.

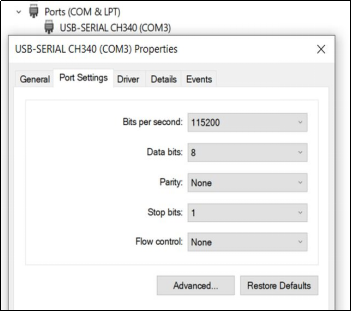

- GRBL is a firmware for arduino boards(uno,nano,Duemillanove) that controls stepper motors and spindles/lasers. GRBL uses gcode as input and outputs signals via the arduino pins. Most industrial cnc machines uses parallel port controller that requires Those big purple connectors. Because GRBL arduino boards you just hook it up to a free usb port.

| $0=10 |

| $1=100 |

| $2=0 |

| $3=5 |

| $4=0 |

| $5=0 |

| $6=0 |

| $10=1 |

| $11=0.010 |

| $12=0.020 |

| $13=0 |

| $20=1 |

| $21=0 |

| $22=1 |

| $23=0 |

| $24=100.000 |

| $25=1000.000 |

| $26=25 |

| $27=1.000 |

| $30=1000 |

| $31=0 |

| $32=0 |

| $100=1600.000 |

| $101=1600.000 |

| $102=1600.000 |

| $110=1100.000 |

| $111=1100.000 |

| $112=1100.000 |

| $120=3000.000 |

| $121=3000.000 |

| $122=3000.000 |

| $130=299.000 |

| $131=179.000 |

| $132=44.000 |

| ok |

| [G54:-147.000,-90.600,-1.500] |

| [G55:0.000,0.000,0.000] |

| [G56:0.000,0.000,0.000] |

| [G57:0.000,0.000,0.000] |

| [G58:0.000,0.000,0.000] |

| [G59:0.000,0.000,0.000] |

| [G28:0.000,0.000,0.000] |

| [G30:0.000,0.000,0.000] |

| [G92:0.000,0.000,0.000] |

| [TLO:0.000] |

| [PRB:0.000,0.000,0.000:0] |

| ok |

commented Jan 6, 2021

Have you gotten this machine to work with software like>> Candle, cncjs, putty, etc??? Candle, cncjs goes no place. |

I did some rough tests and really pushed the 3018 Desktop CNC machine settings to the limits of quality machining. I worked with foam board to diagnose issues, which included inverting the y-axis in Grbl Control Settings. I then tried machining some designs in 1/4 walnut. My feed rate was too high, spindle speed too low, and I was asking it to hog out too much material with its depth of cut and speed combination.

Cnc 3018 Grbl Settings Tool

I also learned that the pre-assembled z-axis assembly, didn’t have a tight enough motor shaft to lead screw connection, when it failed to lift the spindle before a move, and sheered a 1.2mm end mill. That’s why you buy in bulk, right?

For the sake dialing in reasonable expectations, I decided to do some test cuts in acrylic. The black acrylic I had on hand, unfortunately can’t be back lit with LEDs, because it is opaque not transparent, and doesn’t transmit light at all. The quality of cut is still easily observed.

I chose to use a ‘Crash Test Dummy’ head graphic, as it seemed appropriate for a machine, that ‘crashes’ when it fails badly. Fortunately, we never crashed, the machining came out good not great, and I have a better idea of settings to use.

Acrylic Test Machining Settings

Feed Rate: 120 mm/min

Plunge Rate: 60 mm/min

Depth of Cut: 0.8 mm

Spindle Speed: 1000 rpm

End Mill: 1.2mm ti-coated end mill with 1/8 shank

Overall Depth: 2mm

Grbl Settings List

After the experiment on the acrylic, the results were good, but not great. I’m really asking too much of the 775 motor. And short of increasing the motor rpm, which isn’t possible but also the reason to use a real 500 watt or greater spindle, there isn’t really anything to do, but reduce the load. Asking the motor to hog out less material is the solution. A slower feed rate, and .2mm less depth per cut does the trick.

Final Acrylic Machine Settings, Dialed In

Cnc 3018 Grbl Settings

Feed Rate:100 mm/min

Plunge Rate: 60 mm/min

Depth of Cut: 0.6 mm

Spindle Speed: 1000 rpm

End Mill: 1.2mm ti-coated end mill with 1/8 shank